This product is on

Reducing water consumption and provides a natural source for gardening

Lower water bills with grey water and rainwater

RP80 is made from Polyvinylchloride (PVC) and are designed for durability and efficiency in drainage, waste, ventilation, electrical/communication conduit, stormwater, water supply, and irrigation systems. The products are manufactured by Marley New Zealand and are part of a comprehensive range that includes non-pressure and pressure pipes, as well as gutter and downpipe systems.

RP80® 80mm round downpipe has been the most popular downpipe system in New Zealand for over 30 years.

- Streamlined design for greater style

- Compact 43˚ bends available for greater versatility. E.g. tight soffits or stormwater installs

- Adjustable clips with spacers to suit any cladding variation

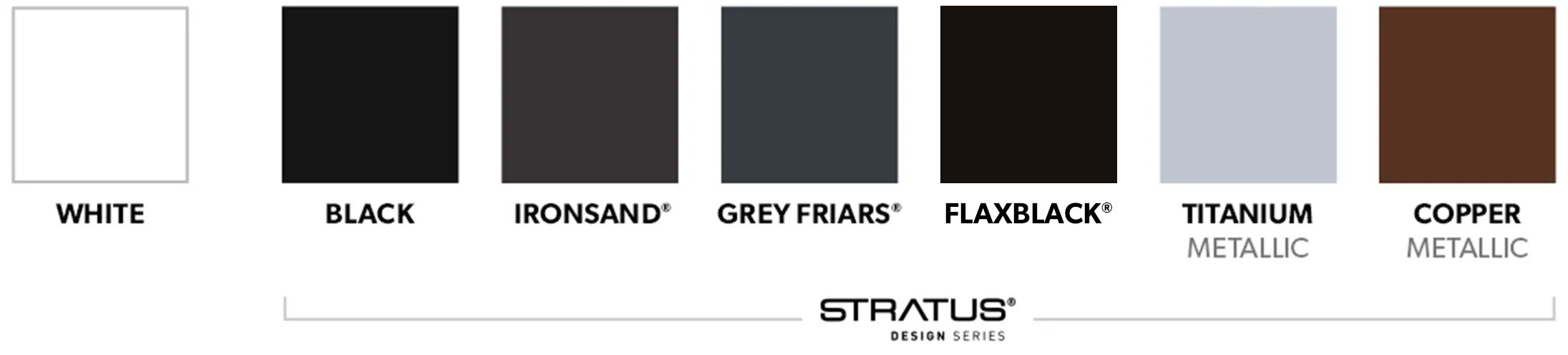

Available in range of colors

15-year guarantee

Currently not available

Global warming potential(A1-A3)

2.69 kgCo2-Eq of embodied carbon per 1kg of RP80® Round Downpipe manufactured.

Global Warming Potential(A4)

0.047 kgCo2-Eq of embodied carbon per 1kg of RP80® Round Downpipe transported from warehouse to the site.

Total Global Warming Potential

2.74 kgCo2-Eq

Currently not available

Used spouting and downpipes can be returned to Marley for recycling

Density: 1,400-1,500 kg/m3

Ultimate tensile strength: 40 - 52MPa

Shore D hardness: 80

Coefficient of linear thermal expansion: 7 x 10-5 / °C

Vicat softening temperature: 74 - 82 °C

Poissons ratio: 0.4

Ring bending modulus: 2,800 – 3,300 MPa

Roof Pitch Roof plane area served by the downpipe (m²)

| Roof Pitch | Roof plane area served by the downpipe (m²) |

|---|---|

| 0° – 25° | 85 |

| 25° – 35° | 70 |

| 35° – 45° | 60 |

| 45° – 55° | 50 |

* Based on average rainfall intensity of 100mm/hr. Refer to BRANZ Bulletin 509.

Bracket System: Flush or stand-off brackets. To be spaced at max 1200mm centres (reduce in high wind areas)

Certified for use with potable water? Yes (certified to AS/NZS 4020)

Environmental certification: ISO 14001, BEP certification

Compatible Marley Spouting systems: Classic™, Stormcloud®, FL2®, Typhoon®

INSTALLATION

Marley downpipe systems are intuitively designed as a modular system, making repair and replacement much simpler. However, there is a technical element to installing Marley downpipes so if you are unsure, Marley recommends you seek advice from a trade professional. Alternatively for a step by step DIY guide, please click here.

Light Reflectance Values

Light reflectance value (LRV) is the total quantity of visible and useable light reflected by a surface in all directions and at all wavelengths when illuminated by a light source. The LRV scale expressed as a percentage ranges from 0, which is the darkest or least reflective, to 100, which is the lightest or most reflective. The LRV percentages of Marley’s rainwater products are:

| COLOUR | LRV % |

| Black | 4 |

| Copper | 15 |

| Grey Friars® | 11 |

| Ironsand® | 8 |

| FlaxBlack® | 7 |

| Titanium | 42 |

| White | 90 |

Downpipe Clip Spacing – Vertical Installation

Place the first downpipe clip a maximum of 200mm from the bend using two stainless steel screws. Ensure the second and subsequent clips are spaced no more than 1.2 metres apart.

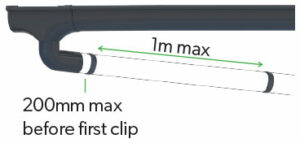

Downpipe Clip Spacing – Horizontal Installation

Place the first downpipe clip no more than 200mm from the bend or junction. Ensure the second and subsequent clips are no more than 1.0m apart. Note that horizontal downpipe should never be installed without a fall away from the spouting. Using a RB2.80 95˚ bend or correctly orientated RJ80 95˚ junction will help ensure a fall as these components have a shallow downward angle built into them.